Understanding Gate Safety Standards

Automatic vehicular gate systems offer convenience and security, but without proper design, installation, and maintenance, they can pose serious risks. Learn how UL 325 and ASTM F2200 work together to ensure safe, compliant, and reliable gate operation.

Related UL 325 and ASTM F2200 Documents

UL 325 and ASTM F2200 Explained:

Automatic vehicular gate operating systems offer both convenience and security to users. Over the past few years, the popularity of these systems has grown significantly. With that growth has come greater awareness of the dangers associated with gates that are not properly designed, installed, used, or maintained. Some gate operators must dangerously apply a high level of force to move the gate. Other systems are installed in areas where pedestrians and vehicles share the same traffic space. In many cases, safety features are either poorly specified or missing entirely.

When a person comes into contact with a moving gate, there is a risk of injury. They may suffer a “pinch” injury, or worse, they may become “entrapped” by the gate.

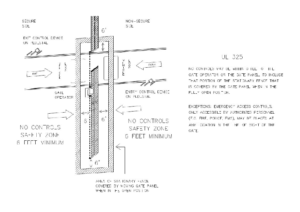

A complete gate system includes several key parts. These are the gate operator, the gate panel, built-in (inherent) entrapment protection devices, external entrapment protection devices, and any screening or physical barriers designed to protect pedestrians near the gate.

If a system is not correctly designed, installed, or maintained, it can cause serious injury or even death to someone near a moving gate.

UL 325 and What to Expect

Over the past thirty months, the UL 325 Standard — officially called Standard for Door, Drapery, Gate, Louver, and Window Operators and Systems — has undergone significant revisions. These changes address growing concerns about the safety of automatic vehicular gate systems.

This information is provided to help you better understand the key parts of the UL 325 standard related to automated gates. It also explains how the standard affects the gate and gate operator industry. Additionally, it highlights some possible future changes to the standard.

Underwriter Laboratories, Inc. (UL) is a not-for-profit organization that was founded in 1894. It describes itself as “the leading third-party certification organization in the United States and the largest in North America.” UL’s primary mission is “to evaluate products in the interest of public safety.”

While UL is widely recognized as a leader in its field, it is not the only certification body. Several other testing laboratories and certification organizations also operate in the United States. However, UL remains the name most people recognize when it comes to product safety standards.

UL standards are considered voluntary standards that set minimum safety requirements for many products on the market today. “Voluntary” means these standards are not mandated by a government or regulatory agency. “Minimum” is also important. It reflects the belief among industry leaders and the standard’s developers that all companies affected by the standard should meet these basic requirements, although some may choose to follow stricter guidelines.

UL standards are developed through an open and collaborative process. UL scientists, industry professionals, and other interested parties contribute to this process to ensure fairness and transparency.

Many UL standards, including UL 325, have undergone a process called a “canvass” or ballot process. This process is designed to gain recognition from the American National Standards Institute (ANSI) as an American National Standard. ANSI designation gives these standards broader public awareness and acceptance.

The canvass process includes input from individuals and organizations who have a direct or material interest in the standard. UL 325 is one of the standards that successfully completed this process and received ANSI designation.

The first edition of UL 325 was released in 1973. This edition primarily focused on the electric operation of garage doors. It did not contain any provisions related to gates or gate operators.

In the early 1990s, federal laws cited the provisions of UL 325 as applicable to garage door operation. Following this, the gate operator industry began including electric gate operator provisions within UL 325. These new provisions were formally established, for all intents and purposes, in September of 1998.

During the development process, government agencies and other interested groups monitored the standard’s progress. They provided input on the final format of the provisions related to gate operators.

On March 1, 2000, a major change took effect. From that date forward, all manufacturers seeking UL listing and labeling for their gate operator products were required to comply with revisions that UL identified as requiring “substantial redesign and retest” of the affected equipment. Additionally, March 1, 2000, marked the start of compliance with the revised installation instructions.

It is important to remember that continual compliance with the standard is required to maintain a product’s listing and labeling status.

For products covered by the standard, UL 325:

-

Contains the basic qualifying factors that products must meet in order to be documented (listed) and marked (labeled) as complying with the requirements of the UL 325 Voluntary Listing and Labeling Program.

-

Provides methods for testing products, primarily related to safety performance.

-

Covers installation of the products in accordance with the National Electric Code, which is maintained by the National Fire Protection Association and is in force nationwide (UL 325 is to be “harmonized” with this code).

-

Addresses safety concerning potential fire and electrical hazards as well as the safety of the general public.

Because of these factors, UL 325 serves as the basis for testing products at a nationally recognized testing laboratory. Gate operator manufacturers who choose to participate in the listing and labeling program must submit their products for testing. If the laboratory finds the products to be in compliance with the UL 325 standard, they are listed and receive a mark (label) indicating compliance.

It is very important to note that laboratories other than UL are capable of listing and labeling products. However, only products tested by UL can receive a UL label. Therefore, the term “UL label” is not a generic term and should not be used that way.

It is also important to understand that UL and other laboratories do not “approve” products. Approval implies accepting responsibility for compliance with the standards. In reality, that responsibility lies with the applying manufacturer, not the laboratory. The burden of proof of compliance always remains with the manufacturer.

In general, UL 325 contains the following highlights related to gate operators:

-

A glossary that defines each type of operator.

-

A separation of gate operators into “classes.”

-

Entrapment protection criteria for each class of operator.

-

Entrapment alarm criteria.

-

Requirements for gate construction and installation.

-

Instructional requirements placing increased responsibility on installers of gates and gate operators.

The term “entrapment,” as used in UL 325 regarding gates and gate operators, is defined as “the condition when an object is caught or held in a position that increases the risk of injury.”

A key part of the UL 325 standard is the table summarizing the entrapment device options for the different classes of gate operators and the various types of gates included in the standard.

We have listed these provisions in the following sections.

To begin with, it is important to understand what qualifies as a “gate” for the purposes of this standard. UL 325 defines a gate as:

“A moving barrier such as a swinging, sliding, raising, lowering, rolling or like, barrier that is a stand-alone passage barrier or is that portion of a wall or fence system that controls entrance and/or egress by persons or vehicles and completes the perimeter of a defined area.”

Based on this definition, UL 325 addresses the following main types of gate operators and systems:

-

Vehicular Barrier (Arm) operator or system: An operator (or system) that controls a cantilever-type device (or system). This consists of a mechanical or barrier arm that moves in a vertical arc. These are intended for vehicular traffic flow at entrances or exits to areas such as parking garages, lots, or toll areas.

-

Vehicular Vertical Pivot Gate operator or system: A vehicular gate operator (or system) that controls a gate moving in a vertical plane. This system is intended for vehicular entrances or exits to a drive, parking lot, or similar area.

-

Vehicular Horizontal Slide Gate operator or system: A vehicular gate operator (or system) that controls a gate which slides in a horizontal direction. This system is intended for vehicular entrances or exits to a drive, parking lot, or similar location.

-

Vehicular Vertical Slide Gate operator or system: A vehicular gate operator (or system) that controls a gate which moves vertically. This system is intended for vehicular entrances or exits to a drive, parking lot, or comparable area.

-

Vehicular Swing Gate operator or system: A vehicular gate operator (or system) that controls a gate swinging in an arc in a horizontal plane. This system is intended for vehicular entrances or exits to a drive, parking lot, or similar location.

It is important to note that, after this initial definition of a gate, all gates and gate operator systems included in UL 325 are defined as vehicular gates and not pedestrian gates.

A key provision in the design and installation of any gate system seeking UL 325 listing is the requirement for a separate pedestrian entrance gate. This pedestrian gate must be located outside of the area used by the automatic gate operating system.

As mentioned earlier, UL 325 separates gate operators into “classes.” For the purposes of this standard, there are four distinct classes of vehicular gate operators, each defined by the type of location and level of access control.

The four classes are as follows:

-

Class I – Residential Vehicular Gate Operator:

A vehicular gate operator (or system) intended for use in garages or parking areas associated with a residence of one to four single families. -

Class II – Commercial / General Access Vehicular Gate Operator:

A vehicular gate operator (or system) intended for use in a commercial location or building. This includes multi-family housing units (five or more single-family units), hotels, garages, retail stores, or other buildings accessible by or servicing the general public. -

Class III – Industrial / Limited Access Vehicular Gate Operator:

A vehicular gate operator (or system) intended for use in an industrial location or building. Examples include factories, loading dock areas, or other locations not accessible by or intended to service the general public. -

Class IV – Restricted Access Vehicular Gate Operator:

A vehicular gate operator (or system) intended for use in a guarded industrial location or building, such as an airport security area or other restricted access locations. In these locations, unauthorized access is prevented through supervision by security personnel.

Some entrapment protection means are authorized only for certain types of gates as shown in the standard. A Type C device, for example, may only be used on a swing gate or barrier arm but not on a slide gate, vertical lift, or vertical pivot gate. The UL 325 standard defines the types of entrapment protection means in the following manner:

Table 32.1 of UL 325 – Protection Against Entrapment

| Gate Operator Category | Entrapment protection types permitted |

|---|---|

| Horizontal Slide, Vertical Lift, Vertical Pivot | A, B1, B2, or D (See definition below) |

| Swing and Vehicular Barrier Arm | A, B1, B2, C, or D (See definition below) |

Note: The same type of devices shall not be utilized for both entrapment protection means. Use of a single device to cover both the opening and closing directions is in accordance with the requirement.

Entrapment Protection Types A, B1, B2, C, and D:

-

Type A: Inherent entrapment protection system.

-

Type B1: Non-contact sensor (Photoelectric sensor or the equivalent).

-

Type B2: Contact sensor (Edge or the equivalent).

-

Type C: Inherent force limiting, inherent adjustable clutch, or inherent pressure relief device.

Note: UL 325 permits these only in swing gates and barrier arms. -

Type D: Actuating device requiring continuous pressure to maintain opening or closing motion of the gate, within line of sight of the gate.

Table 32.2 of UL 325 – Minimum Quantity of Entrapment Protection Means

| Gate Type | Opening Cycle | Closing Cycle |

|---|---|---|

| Horizontal Slide Gate | 2 | 2 |

| Horizontal Swing Gate | 2* | 2* |

| Vertical Pivot Gate | 2 | 2 |

| Vertical Lift Gate | 1 | 1 |

* For a horizontal swing gate operator, at least two independent entrapment protection means are required in each direction of travel.

Except, if there is no entrapment zone in one direction of travel, only one means of entrapment protection is required in that direction of travel; however, the other direction must have two independent entrapment protection means.

Why Should I Install UL 325 Compliant Operators?

The answer is simple: Safety and Liability!

In today’s environment, where risk management is critical, taking every precaution to prevent injuries is essential. UL 325 is a specific standard focused on preventing personal injury from automatic security gates.

This standard addresses two key groups:

-

Gate operator manufacturers, and

-

Gate operator installers

Manufacturers must follow strict guidelines to maintain their UL listing. Installers play a crucial role in completing the UL compliance process. Manufacturers provide specific instructions that installers must follow to ensure compliance.

Installers are responsible for identifying entrapment areas and hazards at their site. The good news is: entrapment is preventable.

The cost of purchasing products, accessories, and installing per UL 325 varies by gate operator type and brand. Slide and swing operators tend to be more expensive to install than Vertical Pivot Gates (VPG) due to additional equipment requirements.

No matter which system you choose, put safety first. Select a UL 325 listed gate operator, identify all possible entrapment zones, and install the proper entrapment protection devices.

The previous sections introduced UL 325, the standard for manufacturing and installing vehicular gate operators. ASTM F2200 addresses many of the same safety concerns but focuses on the gate panel rather than the operator.

ASTM F2200 is the standard used for fabricating and installing vehicular gates designed to be automated. It became effective on July 10, 2002 and includes design and construction standards that fence fabricators and installers use to bridge the gap between operator and gate standards.

This standard applies only to gates intended for automation. If a manual gate is later automated, it must meet the current ASTM F2200 standards before automation.

UL 325 and ASTM F2200 are designed to work together under a harmony principle. Following and understanding these standards helps owners achieve both safety and security from a properly installed automated gate system.

Automated vehicular gates are meant to provide security and control access to property. This creates a delicate balance between security and safety. While security is important, it does not override the responsibility to prevent injuries caused by entrapment, protrusions, pinch points, or even child’s play.

Knowing, understanding, and consistently applying the UL 325 and ASTM F2200 standards is a key part of gate operator installer professionalism.

ASTM F2200 Standards for Gate Construction

ASTM F2200 standards depend on the type of gate and the applicable gate operator. The standard outlines gate construction requirements based on how the gate operates. Even gate types not explicitly described in the standard must still comply with all relevant provisions. (See the Gate Definitions & Types section in the UL 325 part above for reference.)

Some provisions apply to every gate, no matter the type. These include:

-

Gates must have auxiliary supports to prevent them from falling over more than 45 degrees from vertical if detached from their supporting hardware.

-

No protrusions larger than half an inch are allowed on the bottom or vertical edges of the gate. Any protrusions, regardless of length, cannot have sharp edges.

-

Permitted protrusions include top pickets and decorative designs, but only if they stay within the vertical plane of the gate.

-

Barbed wire must be installed at least six feet above the ground, and barbed tape must be installed no lower than eight feet on gates intended for automation.

-

Gates must be balanced so they do not open or close by themselves when disconnected from the operator.

These general requirements apply to all gates. Additionally, there are many other rules specific to gate types such as Horizontal Swing, Horizontal Slide, Vertical Pivot, and Vertical Lift.

It is the responsibility of the gate fabricator and installer to know all ASTM F2200 details and apply them correctly to any gate meant for automation.

No.

Like UL 325, ASTM F2200 is a voluntary standard. This is a legal distinction only and does not mean that installers can ignore it. The term “voluntary” means the provisions do not carry the force of law. Instead, these standards are created by industry groups and establish best practices.

While voluntary, these standards represent a consensus on critical safety measures for the products they cover. Because of this, they can be used to determine liability in cases of injury or death.

Yes.

The Seventh Edition of the UL 325 Standard for Safety for Door, Drapery, Gate, Louver, and Window Operators and Systems has been issued to reflect the adoption of ANSI/CAN/UL 325 as a National Standard of Canada. The most recent designation of ANSI/UL 325 as an American National Standard (ANSI) occurred on May 19, 2017. This standard has also been approved as a National Standard of Canada (NSC) by the Standards Council of Canada (SCC).